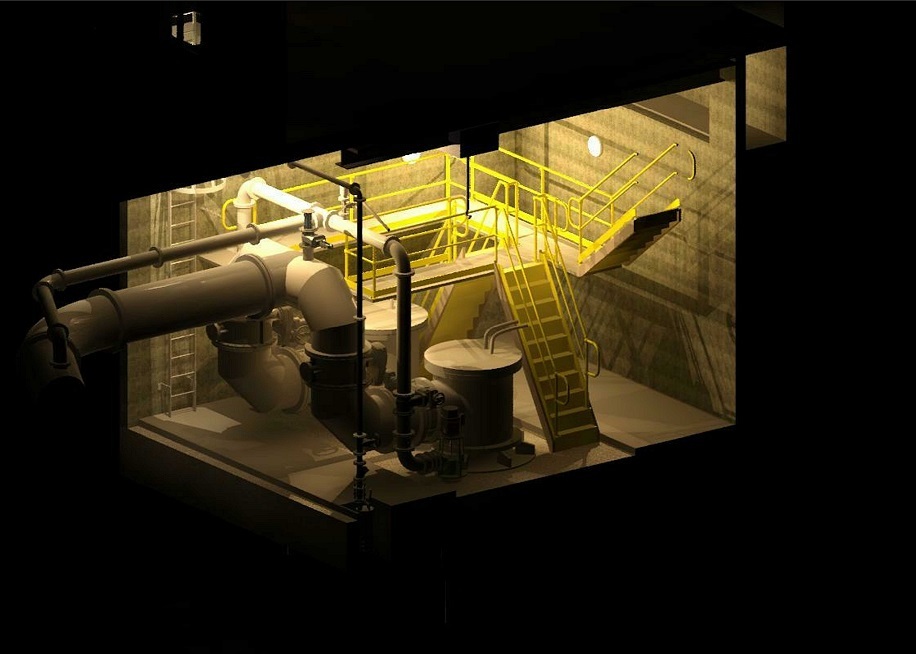

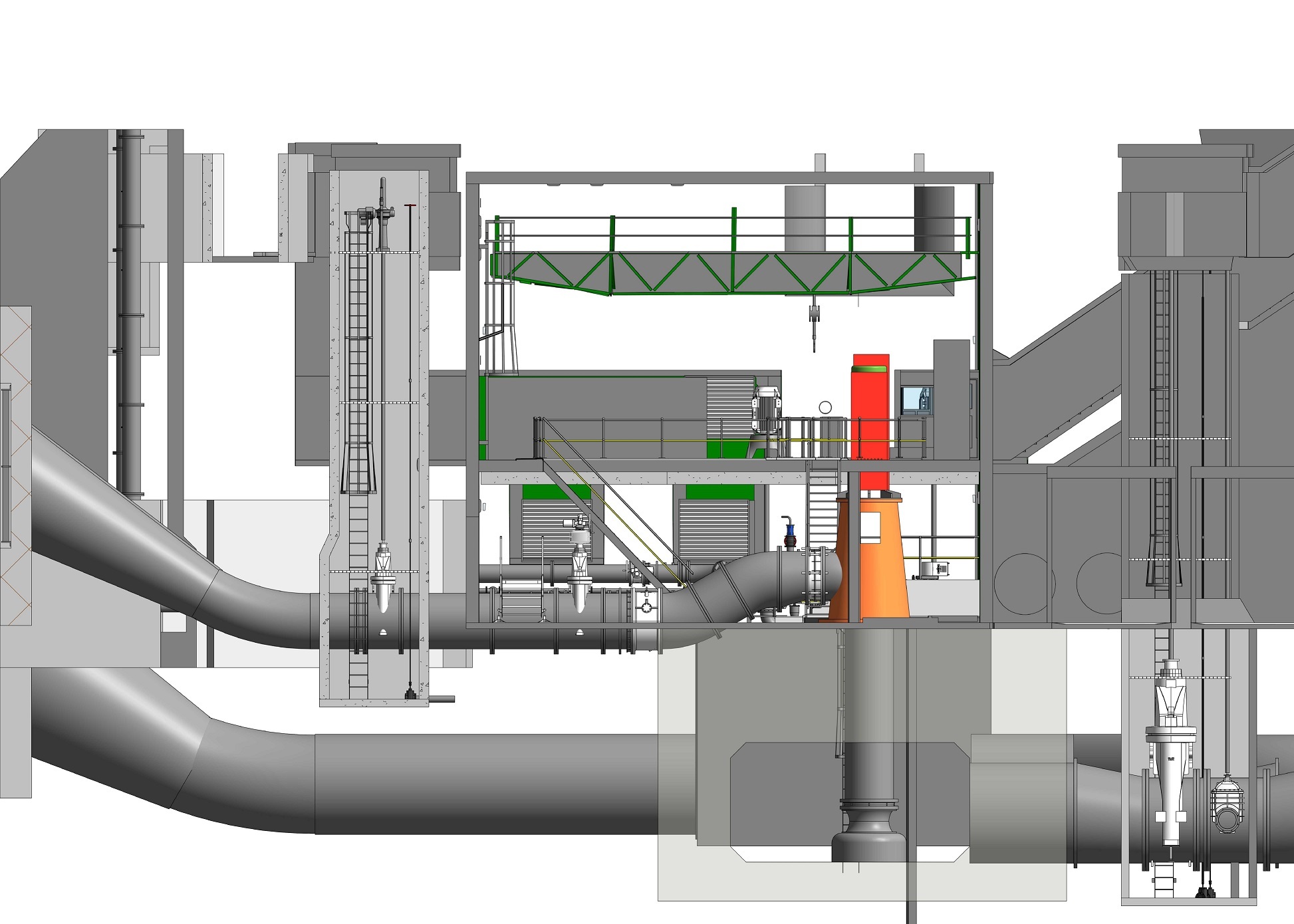

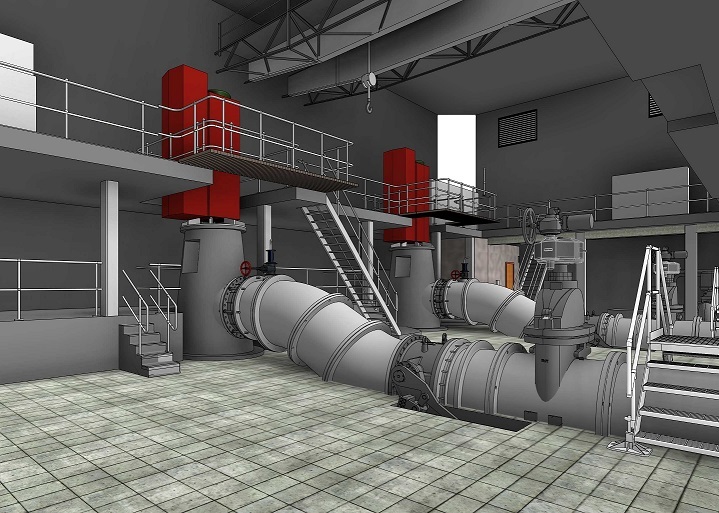

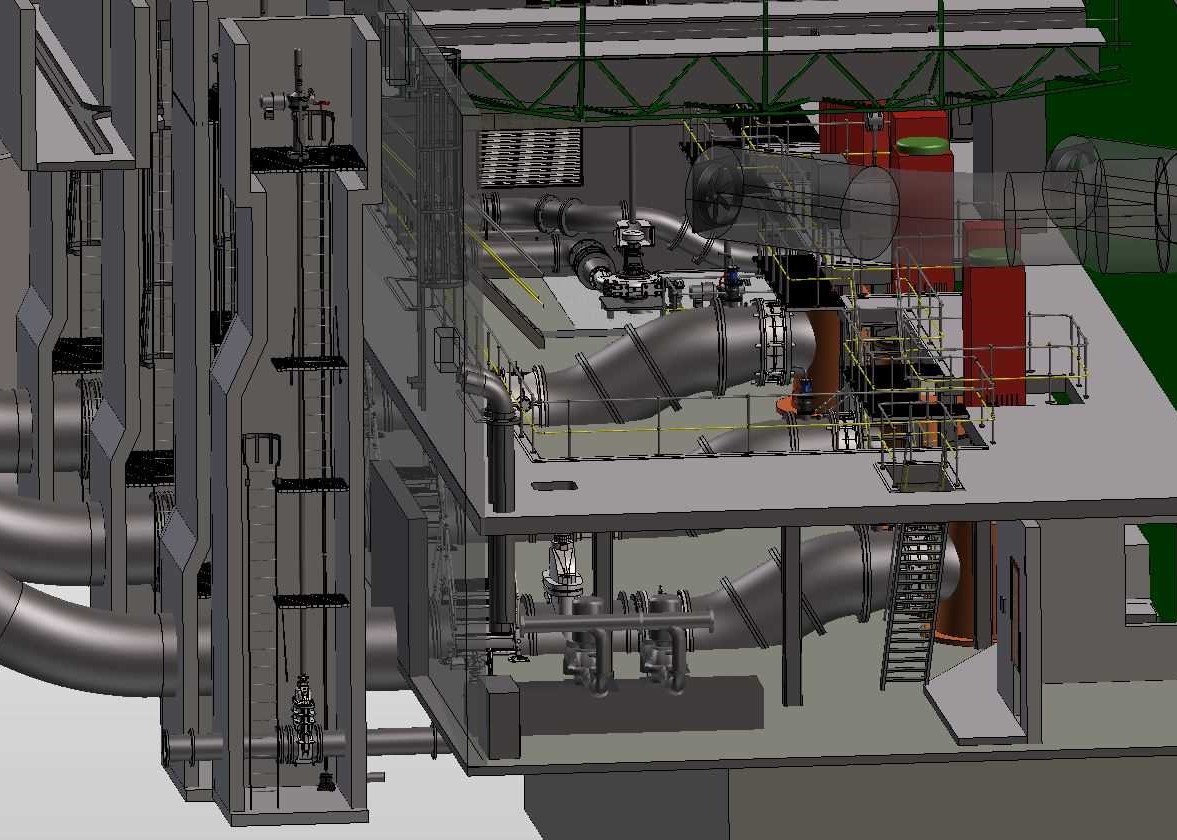

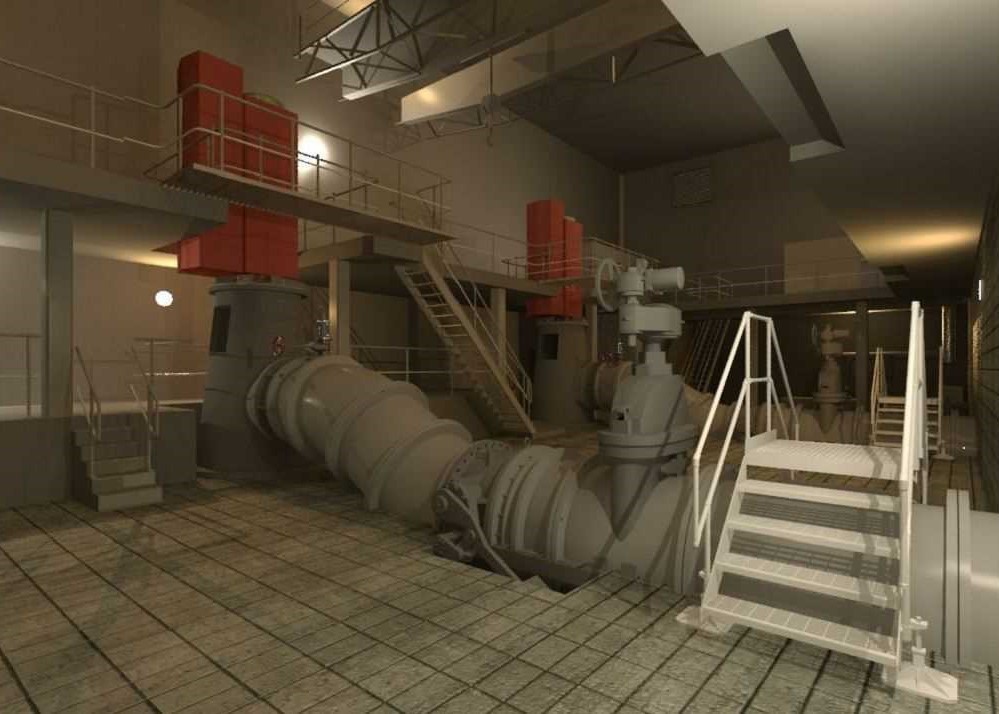

Upgrading of Robinson and Sturrock Dry Dock Dewatering Systems

Client: Transnet

Location: Cape Town, South Africa

MNE OAK, in collaboration with Aurecon SA, was appointed for the detail design and feasibility study (FEL3 Phase) related to the mechanical and electrical engineering scope of this project. The consulting scope included Technical Status Quo Report, Hydraulic Analysis, Detailed Design Drawings, Specifications and Bills of Quantities for said scope.

The scope includes all pumps, pipework, bulk electrical supply, electrical motor control, instrumentation, telemetry and SCADA requirements

Beaufort West Borehole and Bulk Water Scheme

Client: Beaufort West Municipality

Location: Beaufort West

MNE OAK was the responsible mechanical and electrical consultants on this project. The consulting scope included system design, specification, procurement management, all aspects of quality control, and commissioning and testing once completed.

The project was implemented in three (3) phases:

Phase 1:

Equipping of 1 x New Borehole and Refurbishment of 2 x Existing Boreholes

Phase 2:

Upgrading of Existing Booster Pump Station and the refurbishment of 2 x Existing Boreholes

Phase 3:

Equipping of 5 x New Boreholes and 1 x New Lift Pump Station

The scope includes all pumps, pipework, electrical bulk supply, electrical motor control and instrumentation, Telemetry and SCADA requirements for remote control monitoring.

Vredenburg Splash Park

Client: WEC Consult/Saldanha Bay Municipality

Location: Vredenburg, Western Cape

Instead of a traditional municipal type swimming pool, the client opted for a ‘Splash Park’ where children of the community can go to enjoy some outdoor activity while cooling down during summer.

A splash park contains various themed water features that spray, splash or jet water onto children playing in the park.

MNE OAK was part of the professional team assigned to this project, and was responsible for the design and project management of all mechanical and electrical related elements of this park. These aspects included:

Electrical Supply to Site

Electrical Reticulation and Distribution

Site Lighting

Pumping Systems - Filtration and Pressure Boosting

Water Treatment - Filtration, Dosing and Disinfection, Storage Tanks

Electrical Control and Instrumentation for the entire system

Williston Boreholes and Bulk Water Scheme

Client: Karoo Hoogland Municipality

Location: Williston, Northern Cape

MNE OAK was the responsible mechanical and electrical engineering consultants on this project. The consulting scope included system design, specification, procurement management, all aspects of quality control, and commissioning and testing once completed.

The project was implemented in three (3) phases:

Phase 1:

Equipping of 2 x New Boreholes and Refurbishment of 1 x Existing Boreholes

Phase 2:

Equipping of 1 x New Borehole and Refurbishment of 1 x Existing Borehole

Phase 3:

Equipping of 5 x New Boreholes, Refurbishment of 5 x Existing Boreholes,

and 1 x New Lift Pump Station (2 Boreholes with Solar Electrical Supply)

The scope includes all pumps, pipework, electrical bulk supply, electrical motor control and instrumentation, emergency power, Telemetry and SCADA requirements for remote control and monitoring.

Unifrutti Pack Store - Phase 1A

Client: Unifrutti, SA

Location: Redelinghuys, Western Cape

A new grape and citrus Pack Store is currently under construction outside the town of Redelinghuys, complete with on-site cooling facilities.

MNE OAK is part of the professional team (design, project and contract management), responsible for all bulk electrical, distribution, lighting, power and energy efficient elements of this project.

These aspects include:

22kV Bulk Electrical supply to site

LV DBs, metering and power distribution throughout the site

Internal and external lighting designs

Small power feeds to all automated plant equipment, drives, DBs and motors

Waste Water Reticulation Network Investigation and Report

Client: Knysna Municipality

Location: Sedgefield, Southern Cape

The client upgraded the Sedgefield Waste Water Treatment Works as part of this project.

MNE OAK was part of the professional team responsible for assessing the existing waste water system/infrastructure and identifying means for improvement as well as the reduction of loads to the Waste Water Treatment Works.

The measures identified included the upgrading of the four (4) main Waste Water Pump Stations and its control philosophies. These were successfully implemented by the contractor with the system thoroughly tested by MNE OAK and handed over to the client.

Aeration System - Municipal Waste Water Treatment Works

Client: Cape Agulhas Municipality

Location: Bredasdorp, Western Cape

One of the key components in the treatment of waste water is aeration. The process involves adding oxygen and agitation to the effluent.

The clients existing aeration system involved Orbal Disc type aeration as part of the Orbal Pond. Maintenance and repairs to this system became too frequent and expensive. MNE OAK was responsible for the consulting services (design, project management, quality control and testing) of the retrofitted Propeller/Venturi type aeration system. This technology made operations more flexible in terms of optimising oxygen transfer requirements as well as easier maintenance of the equipment.

As part of the project, ancillary works included the cleaning and repair of the inlet works and related pump station and refurbishment to clarifiers.

The client is now better enabled to manage the oxygen transfer/dissolved oxygen and suspended solids in the Orbal Aeration Pond as well as have a healthier and more efficient treatment works.

SAFT Alternative Water Supply Project

Client: SAFT - South African Fruit Terminals

Location: Killarney Gardens, Western Cape

With the recent drought and water restrictions, many industrial water users investigated optimisation strategies and alternative water sources/systems to reduce the load and costs related to the municipal water system. SAFT was one such client who opted for alternative water from a borehole that existed on site, initially to supply water to their chiller plant. The borehole water required treatment to SANS 241 Drinking Water standard for use in the chillers. When this requirement was identified, it was decided to reticulate this water in the entire site network.

MNE OAK was the turnkey solution provider, responsible for the design, supply, installation, commissioning and testing of the alternative water supply system. This included:

Borehole System – Pump, pipework, pipeline, electrical control and protection, Raw water tanks

Water Treatment System – Pre-filtration - 3 Stage Filtration, Reverse Osmosis (RO) Plant, Silliphos Filtration, UV Sterilization

Pressure Booster Pumping System

Fruit PackStore

Client: Lucerne Pack

Location: Robertson, Western Cape

A new fully-automated Pack Store, in excess of 10, 000m2, was constructed outside the town of Robertson. The automated sorting and packing lines can handle different fruits for supermarket distribution.

MNE OAK was part of the professional team (design, project and contract management and close-out), responsible for all bulk electrical, distribution, lighting, power and energy efficient elements of this project.

These aspects included:

11kV Bulk Electrical supply to site

LV DBs, metering and power distribution throughout the site

Internal and external lighting designs

Small power feeds to all automated plant equipment, drives, DBs and motors

Power Factor Correction implementation

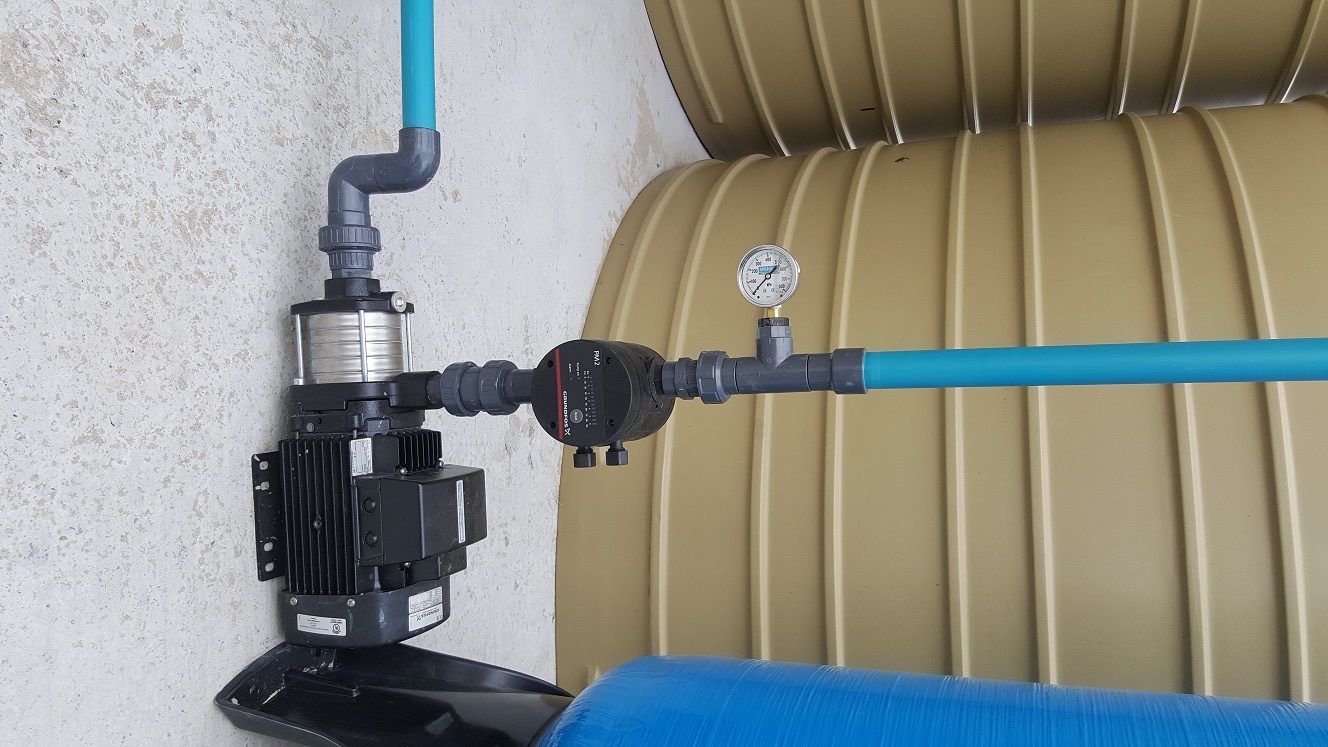

MPACT Alternative Water Supply Project

Client: MPACT VERSAPAK

Location: Paarl, Western Cape

With the recent drought and water restrictions, many industrial water users investigated optimisation strategies and alternative water sources/systems to reduce the load and costs related to the municipal water system. MPact Versapak was one such client who opted for alternative water from a borehole that existed on site.

MNE OAK was the turnkey solution provider, responsible for the design, supply, installation, commissioning and testing of the alternative water supply system.

This included:

Borehole System – Pump, pipework, pipeline, electrical control and protection, Raw water tanks

Water Treatment System – Pre-filtration, Settling Process, 3 Stage Filtration, UV Sterilization

Pressure Booster Pumping System

Solar Powered Final Effluent Pumping System

Client: Hessequa Municipality

Location: Jongensfontein, Stilbaai - Western Cape

Jongensfontein is a small holiday town with a small waste water treatment works (WWTW) that experiences peaks over holiday periods.

MNE OAK was responsible for the design, supply and installation of a suitable pumping solution to irrigate the final effluent on the surrounding areas as well as recycle the effluent in the plant as part of the required process operation.

The challenge here being that there was no electrical supply to the WWTW and the solution had to be based on renewable energy (solar) as well as petrol generator in the event of cloudy/rainy weather over long periods.

The installation involved 1.5 kW pumps, related pipework and fittings, controller for solar and generator, and 18 x 260W (4.7 KW) Solar Panels pole mounted.

The system works better than was planned and designed and the client is totally satisfied.

Ground Water Abstraction Scheme and Water Treatment Plant

Client: Cape Town Film Studios

Location: Cape Town

The client historically used municipal drinking water for movie sets requiring water, as well as various processes involved.

Given the recent drought situation in the Western Cape, the client embarked on a project to investigate the use of ground water to fulfill the same requirement instead.

MNE OAK is involved with the master planning of the proposed scheme and for the design, supply and installation of equipment for 4 x Ground water abstraction systems. Each of these abstraction systems pumps water to a centralized Water Treatment Plant.

The Water Treatment Plant was part of the second phase of the project and included an Iron Removal and Settlement Process, 3 Stage Filtration, UV Sterilization, Waste and Final Product Pumping Systems.

Solar Pool Pump Retrofit

Client: Timour Hall Primary School

Location: Plumstead, Cape Town

The School has an established swimming pool for the programme.

The pool pumping system constisted of 4 x 1.1 kW pool pumps, costing the school in excess of R 1700-00 per month in electricity to operate.

MNE OAK took on the opportunity as CSR Project and lobbied suppliers to come on board.

The Solution

- Current Costs to run the school pool pumps per month R 1700-00

- Normal Cost of System Installed – R 160 000-00 Vat incl.

Donations:

- Grundfos South Africa – 2 x Solar Pool Pumps

- Mr and Mrs Augustyn – 2 x Solar Pool Pumps

- MNE OAK – Consulting Engineering and Project Management Services - Free

- Flex Solar – Discounted Installation (25%)

- Solar Solved Africa – Supply of Solar Panels at Cost Price

Further Benefits/Advantages to School:

- Saving of more than R 13 000-00 per annum, increasing annually

- Pool pumps can still run in Winter at no electrical cost

- Healthier Pool with higher filtration/volume turnover at no additional cost

- Less pool shock treatment and chemicals needed after pumping less/no pumping during winter

- Timour Hall Primary School Goes Green Initiative

- Contribution to reduced Carbon Footprint

- Bragging rights of one of first Schools to convert pool to solar. (To my knowledge as least – I cannot confirm this as fact.)

- Further Opportunities for Sponsorship/Donations for Return Branding/Mileage based on schools location and passing traffic.

Plant Power Factor Correction

Client: Woody's Brands

Location: Cape Town

With electricity costs rising much faster than inflation, any potential savings for high energy users must be considered. Given the electricity rates structure, Clients are billed on their electricity usage, but also peak usage (kVA) during that month. Woody's existing power factor (pf) correction system was no longer functioning optimally, with pf values during peak periods in the region of 0.9. MNE OAK facilitated the due diligence inspections, reported on findings and technical recommendations and implemented modifications/replacement of the pf equipment to increase the site's pf values, during the peak periods, to close to unity.

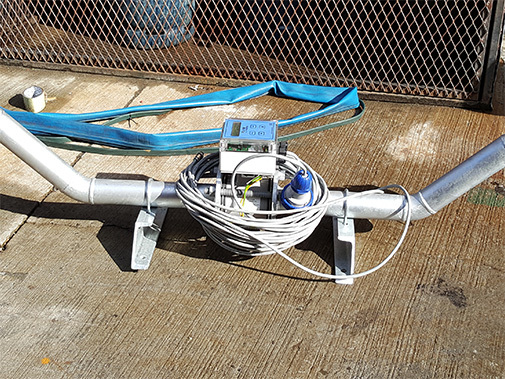

Commissioning, Testing, Training and Operations

Client: Geoss

Location: Western Cape

MNE OAK was instrumental to this client with many aspects of their Borehole Testing Rig,

The rig is used to test boreholes after initial drilling to ensure that the water abstracted is done at a sustainable rate which is not harmful to the aquifer.

MNE OAK initially got involved with the concept design of the pumping and control equipment with in relation to the actual testing requirement, followed by incorporating into the all inclusive trailer and testing rig.

MNE OAK followed through by ensuring that the system worked as planned, fulfills the clients needs completely and ensuring that operations staff are adequately trained to use the machine.

This was an exciting opportunity as we believe that this testing rig is the first of its kind in South Africa and reduces the overall testing time drastically.